How Is Aluminium Extruded?

In the realm of manufacturing and industrial innovation, aluminium extrusion stands as a testament to precision and versatility. This process, crucial for creating custom aluminium extrusions and profiles, plays a pivotal role in various industries worldwide.

At its core, aluminium extrusion begins with raw aluminium ingots. These ingots are heated to a precise temperature, nearing 900 degrees Fahrenheit, to achieve optimal malleability. The molten metal is then forced through a shaped die—a carefully designed tool that imparts the desired cross-sectional profile to the extruded aluminium.

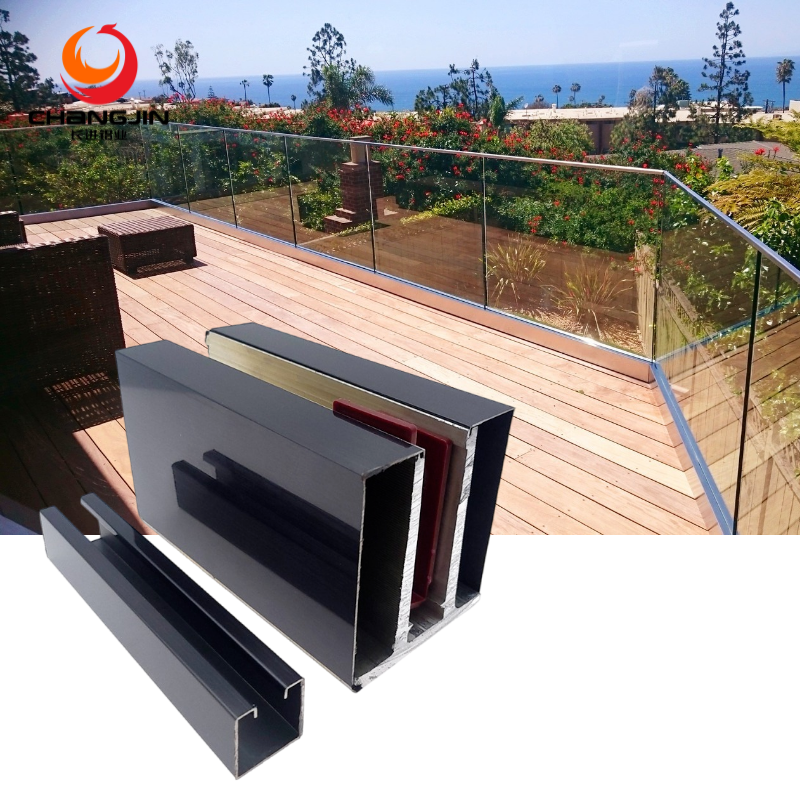

Precision is key throughout this process. The die itself, crafted from hardened steel, determines the exact dimensions and characteristics of the extrusion. From simple shapes to intricate designs, the versatility of aluminium extrusion allows for the creation of a wide range of profiles tailored to specific applications. Whether it‘s for architectural frameworks, automotive components, or intricate electronic enclosures, each profile can be customized to meet stringent design requirements.

Once extruded, the aluminium profiles undergo a cooling process to ensure structural integrity and dimensional accuracy. Post-extrusion, the profiles may be subjected to additional treatments such as heat treatment, surface finishing, or precision cutting to achieve the final product specifications.

Aluminium extrusion not only offers design flexibility but also boasts environmental benefits. Aluminium is highly recyclable, with nearly 75% of all aluminium ever produced still in use today. This sustainability factor makes aluminium extrusions a preferred choice for industries aiming to minimize their carbon footprint.

Moreover, the demand for custom aluminium extrusions continues to grow, driven by advancements in technology and industry-specific requirements. Manufacturers increasingly rely on bespoke solutions that aluminium extrusion provides, offering unparalleled strength-to-weight ratio and corrosion resistance.

Aluminium extrusion represents a cornerstone of modern manufacturing, enabling the creation of intricate profiles that serve diverse applications worldwide. As industries evolve, so too does the demand for custom aluminium extrusions—pushing the boundaries of what is possible in design, efficiency, and sustainability.

For more updates on advancements in aluminium extrusion and related technologies, stay tuned to our news channel for the latest developments.