Aluminum Extrusion Innovations Propel Solar Frames into Maritime Applications

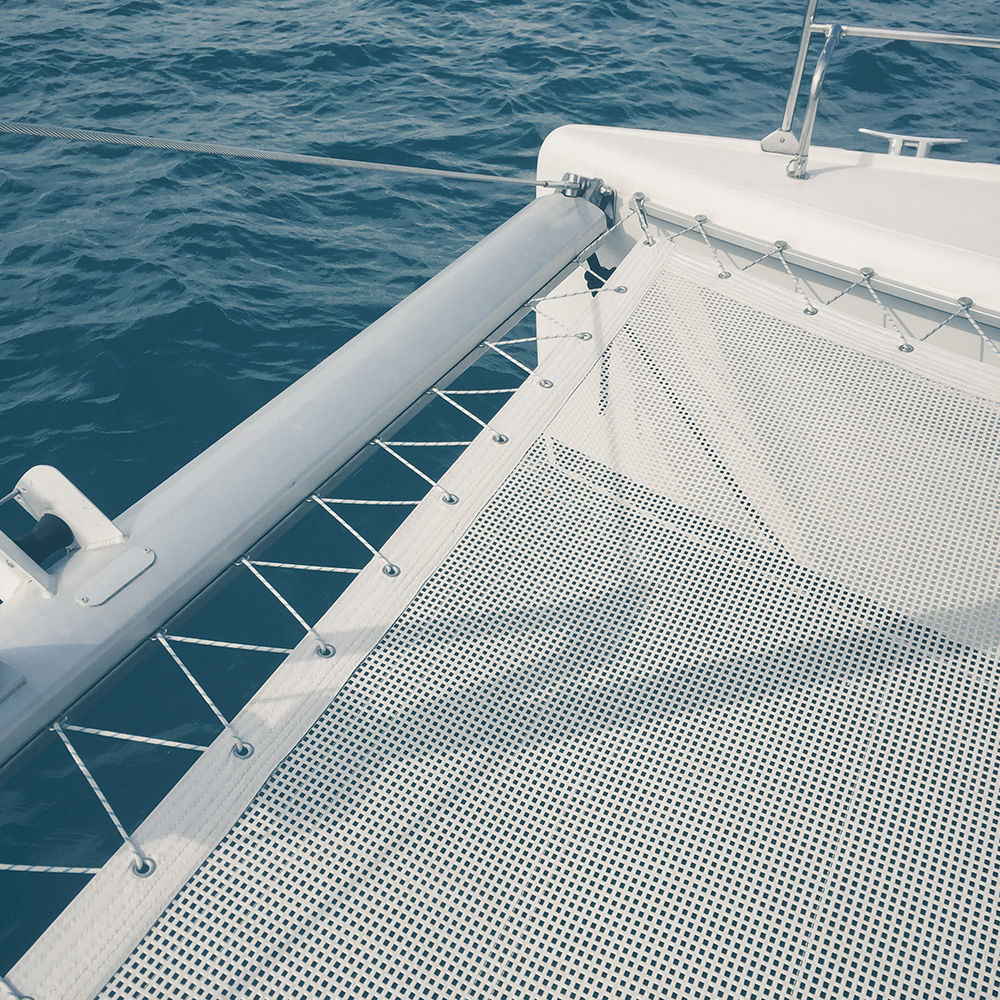

In a groundbreaking move within the aluminum extrusion industry, the role of aluminum frames in maritime applications is set to undergo a transformative shift. Solar technology, known for its sustainable energy benefits, is increasingly relying on aluminum extrusions to enhance efficiency and durability in maritime environments.

Why Aluminum Extrusion Matters:

Aluminum extrusion, a process vital to shaping aluminum into custom profiles, has long been pivotal in industries requiring lightweight, corrosion-resistant solutions. Its versatility makes it ideal for solar panel frames, offering strength without compromising on weight—a critical advantage in maritime installations where both stability and longevity are paramount.

Advancing Solar Technology:

Recent advancements in aluminum extrusion techniques have enabled the development of frames specifically tailored for maritime applications. These frames not only withstand the rigors of sea climates but also provide a secure mounting structure for solar panels on ships, offshore platforms, and other marine vessels.

Key Benefits Highlighted:

Corrosion Resistance: Aluminum‘s natural oxide layer provides excellent protection against saltwater corrosion, ensuring prolonged durability even in harsh maritime conditions.

Lightweight Design: By utilizing aluminum extrusions, solar frames maintain a lightweight profile essential for marine applications, reducing overall structural weight without compromising strength.

Customizability: The flexibility of aluminum extrusion allows for precise customization of frame profiles, accommodating various panel sizes and mounting configurations.

Industry Insights:

Industry experts emphasize that the integration of aluminum extrusions in maritime solar applications marks a significant advancement in sustainable energy solutions. The ability to harness solar power effectively at sea not only reduces reliance on conventional fuels but also contributes to environmental conservation efforts.

Future Prospects:

Looking ahead, the aluminum extrusion industry anticipates further innovations in material compositions and manufacturing techniques. These innovations aim to enhance the efficiency and cost-effectiveness of solar installations across diverse maritime settings, promoting the widespread adoption of renewable energy sources.

Conclusion:

As solar technology continues to evolve, the role of aluminum extrusions in maritime applications underscores a pivotal synergy between sustainability and advanced engineering. By leveraging the inherent strengths of aluminum extrusions, the industry is poised to drive forward the adoption of solar power in maritime environments, paving the way for a greener and more resilient future.

This development not only highlights the versatility of aluminum extrusions but also underscores their crucial role in shaping the future of sustainable energy solutions worldwide.